CRITICAL METALS CORP NASDAQ-CRML Acquires an Integrated Rare Earth Element Assay Analysis Lab Facility to Support Faster Drilling Assay Results for 2026 Drilling Campaign at Tanbreez

- Strategic rationale: Critical Metals Corp has approved and ordered a turnkey Integrated Mobile Geochemical Analysis Centre from Bromet to support the Tanbreez rare earths project, including pilot plant activities and ongoing project development.

- Ownership and operation: The assay laboratory is expected to be acquired by the Company and operated exclusively for CRML by trained Greenlandic personnel, with analytical results subject to oversight and validation by an independent, appropriately accredited third party.

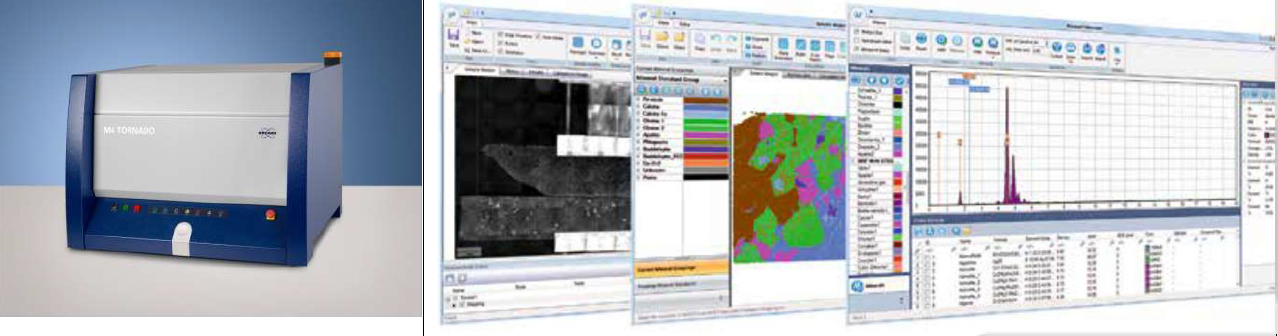

- On-site analytical capability: The facility will incorporate a Bruker M4 Tornado Plus 26S Micro XRF system, designed to enable real-time, on-site “mine-to-data” geochemical analysis and to generate full elemental rare earth element (REE) results in approximately 80 minutes, significantly reducing assay turnaround times compared to traditional off-site laboratory processing.

- Operational efficiency and ESG considerations: The modular, mobile laboratory solution is expected to enhance exploration efficiency, grade control, and operational decision-making, while reducing reliance on off-site laboratories, sample transport requirements, and associated time delays, consistent with Environmental, Social and Governance (ESG) considerations.

- Project advancement: The investment is expected to support faster data generation for future drilling campaigns, assist in the evaluation and potential expansion of mineral resources in accordance with applicable SEC Regulation S-K 1300 requirements, and improve the timeliness of information available to the Company, potential offtake partners, and shareholders.

-

Regulatory approvals: Commissioning and operation of the facility in Greenland will be subject to applicable government and regulatory approvals.

NEW YORK, Jan. 12, 2026 (GLOBE NEWSWIRE) -- Critical Metals Corp. (Nasdaq: CRML) (“Critical Metals Corp” or the “Company”), a leading critical minerals mining company, today announced that it has ordered a fully turnkey Integrated ~US$1m Mobile Geochemical Analysis Centre from Bromet, a leading provider of advanced mining laboratory solutions. This acquisition represents a significant investment in technical capability and underscores the Company’s commitment to operating as a world-class mining organization while advancing the Tanbreez rare earth elements (“REE”) project.

Tony Sage, Chief Executive Officer of Critical Metals Corp., commented:

“The acquisition of the Integrated Mobile Geochemical Analysis Centre marks a transformative milestone for Critical Metals as we propel the Tanbreez rare earths project from exploration into pre-mining pilot operations. Having the capability to perform laboratory-grade geochemical analysis directly at site is expected to significantly accelerate our data collection, sharpen real-time decision-making, and strengthen our assessment of Tanbreez’s exceptional resource potential and long-term scalability. This strategic investment reinforces our commitment to technical excellence, disciplined project advancement, and unlocking substantial value from one of the world’s most important emerging rare earths assets. It also reflects our dedication to building local capacity by supporting the training and development of Greenlandic personnel as we advance this globally significant project.”

The Integrated Mobile Geochemical Analysis Centre is an industrial-grade, mobile laboratory designed to deliver real-time, on-site geochemical data directly at the mine site. This state-of-the-art facility is intended to support the Company’s proof-of-concept pilot plant by enabling rapid, laboratory-grade elemental analysis of samples derived from drill core and pilot plant material. The system incorporates crushing and sample preparation capabilities together with automated Micro XRF analysis, and is designed to generate full rare earth element (REE) results in under approximately 80 minutes using a Bruker M4 Tornado Plus 26S Micro XRF system and associated software.

The system is designed to enable a “Mine-to-Data” workflow, which is expected to materially reduce assay turnaround times compared to traditional off-site laboratory processing and support more timely decision-making across exploration, grade control, and mine planning activities. By providing laboratory-grade analytical capability on site, Critical Metals expects to reduce reliance on external laboratories and enhance the speed of geological interpretation and operational execution.

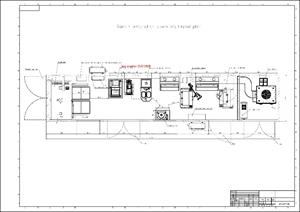

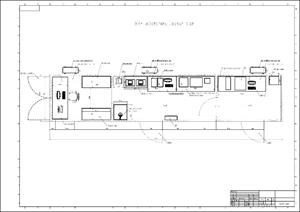

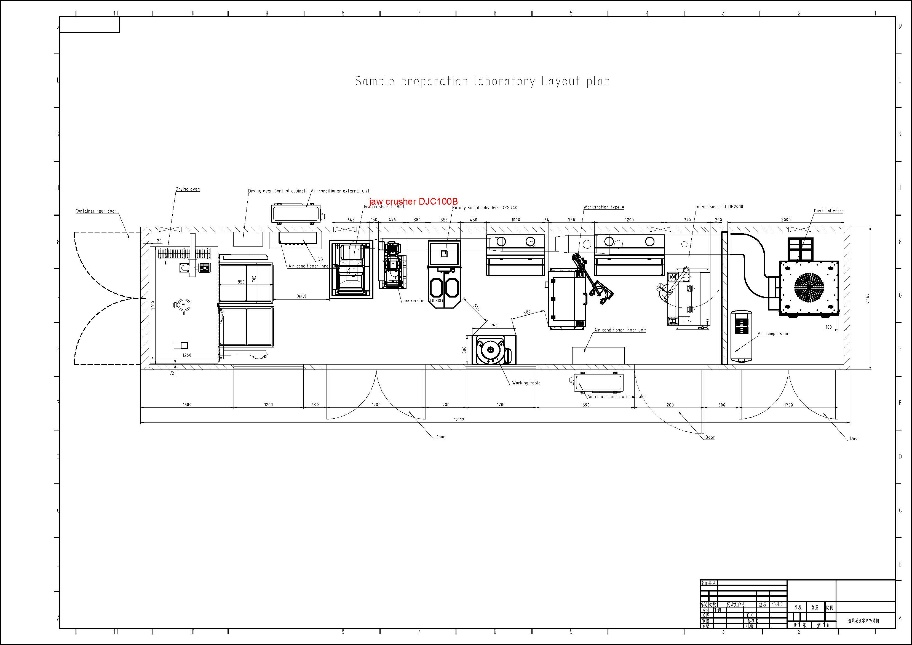

The facility comprises two customized 40-foot high-cube modular units designed for rapid deployment and relocation, supporting both early-stage exploration and ongoing production activities. The system has been configured to operate in Greenlandic conditions.

Module A provides automated, high-throughput sample preparation, including crushing, representative sub-sampling, pulverizing, and drying. The module incorporates integrated dust control, safety systems, and environmental safeguards to meet stringent industrial occupational health, safety, and environmental standards.

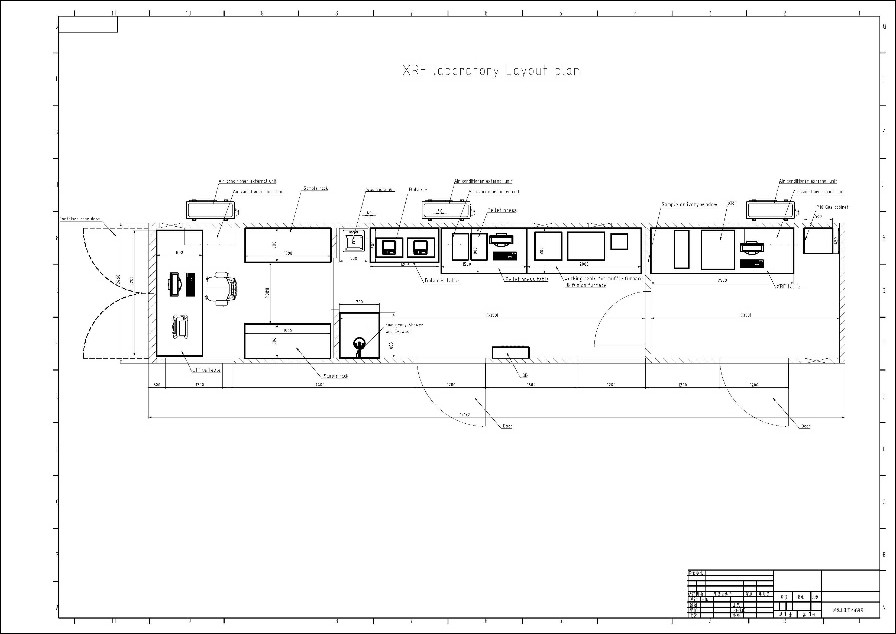

Module B houses a climate-controlled state of the art X-ray fluorescence (XRF) analytical and data processing laboratory. This module includes pellet pressing, precision weighing, and contamination-controlled workspaces intended to support analytical accuracy, data integrity, and reproducibility. The automated workflow is designed to minimize human error and generate consistent, verifiable datasets suitable for internal decision-making and public disclosure.

The solution aligns strongly with Environmental, Social, and Governance (ESG) considerations through advanced dust extraction systems, safety interlocks, and reduced sample transport requirements. Its modular and mobile design is expected to enhance asset utilization across multiple projects, providing a scalable and repeatable platform as the Company advances its broader development strategy.

Management believes that the addition of the Integrated Mobile Geochemical Analysis Centre further strengthens Critical Metals’ technically capability and execution focus, supporting development activities at the Tanbreez project while contributing to the training and development of Greenlandic personnel.

Figure 1. Sample Preparation Area

Figure 2. XRF Lab External View

Figure 3. Micro XRF and Geo-chemical Software

Figure 4. Sample Prep Lab Layout

Figure 5. XRF Room Layout

About Critical Metals Corp.

Critical Metals Corp (Nasdaq: CRML) is a leading mining development company focused on critical metals and minerals, and producing strategic products essential to electrification and next generation technologies for Europe and its western world partners. Its flagship Project, Tanbreez, is one of the world's largest, rare-earth deposits and is in Southern Greenland. The deposit is expected to have access to key transportation outlets as the area features year-round direct shipping access via deep water fjords that lead directly to the North Atlantic Ocean.

Another key asset is the Wolfsberg Lithium Project located in Carinthia, 270 km south of Vienna, Austria. The Wolfsberg Lithium Project is the first fully permitted mine in Europe and is strategically located with access to established road and rail infrastructure and is expected to be the next major producer of key lithium products to support the European market. Wolfsberg is well positioned with offtake and downstream partners to become a unique and valuable asset in an expanding geostrategic critical metals portfolio.

With this strategic asset portfolio, Critical Metals Corp is positioned to become a reliable and sustainable supplier of critical minerals essential for defense applications, the clean energy transition, and next-generation technologies in the western world.

For more information, please visit https://www.criticalmetalscorp.com/.

Cautionary Note Regarding Forward Looking Statements

This news release contains forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”). Forward-looking statements may include expectations of our business and the plans and objectives of management for future operations. These statements constitute projections, forecasts and forward-looking statements, and do not guarantee performance. Such statements can be identified by the fact that they do not relate strictly to historical or current facts. When used in this news release, forward-looking statements may be identified by the use of words such as “estimate,” “plan,” “project,” “forecast,” “intend,” “will,” “expect,” “anticipate,” “believe,” “seek,” “target,” “designed to” or other similar expressions that predict or indicate future events or trends or that are not statements of historical facts. In addition, any statements that refer to projections, forecasts or other characterizations of future events or circumstances, including any underlying assumptions, are forward-looking statements.

Forward-looking statements are subject to known and unknown risks and uncertainties and are based on potentially inaccurate assumptions that could cause actual results to differ materially from those expected or implied by the forward-looking statements. Actual results could differ materially from those anticipated in forward-looking statements for many reasons, including the factors discussed under the “Risk Factors” section in the Company’s Annual Report on Form 20-F filed with the U.S. Securities and Exchange Commission. These forward-looking statements are based on information available as of the date of this news release, and expectations, forecasts and assumptions as of that date, involve several judgments, risks and uncertainties. Accordingly, forward-looking statements should not be relied upon as representing our views as of any subsequent date, and we do not undertake any obligation to update forward-looking statements to reflect events or circumstances after the date they were made, whether as a result of new information, future events or otherwise, except as may be required under applicable securities laws.

Critical Metals Corp.

Investor Relations: ir@criticalmetalscorp.com

Media: pr@criticalmetalscorp.com

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/7c4f58b9-3f37-47ab-9526-730c314840a0

https://www.globenewswire.com/NewsRoom/AttachmentNg/649baa5a-f1e4-4e24-badd-63407f6e6181

https://www.globenewswire.com/NewsRoom/AttachmentNg/fad6d0df-8b8d-43b6-ab58-2a4342e9ab54

https://www.globenewswire.com/NewsRoom/AttachmentNg/26b8db2a-53c2-45ee-9f35-663c89a78b9c

https://www.globenewswire.com/NewsRoom/AttachmentNg/bb60ff60-6483-4020-8f74-acba78572110

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.